Mastering Melt Stream Delivery: The Power of Husky's Integrated Systems

The quality of countless products, from the smallest most complex consumer electronics and packaging parts to mission critical medical components, often depends on a process that is largely hidden from view: melt stream delivery. This is, in many ways, the unsung hero of injection molding, and at Husky, we've made it our mission to master this critical aspect of manufacturing.

In this article, we'll pull back the curtain on this crucial process to take a closer look at why melt stream delivery is important, the challenges many manufacturers are facing, and how Husky's integrated approach can enable you to overcome them.

The Importance of Melt Stream Delivery

What is melt stream delivery, anyway? Melt stream delivery refers to the control flow of molten plastic, from the injection unit through the hot runner system and into the mold cavity. This part of the production process can sometimes be overlooked, but efficient and precise melt stream delivery is a hallmark of a well-engineered system, and it can have a direct impact on every aspect of production.

Optimal melt stream delivery enables:

- Consistent part quality and dimensional accuracy: Uniform melt conditions lead to superior dimensional accuracy and consistent mechanical properties, reducing variability across production runs.

- Efficient material usage with minimal waste: An optimized system efficiently directs molten plastic into the mold cavity, minimizing waste, and reducing costs and environmental impact.

- Faster cycle times: Efficient melt delivery enables quicker mold filling, which reduces cycle times and boosts overall production.

- Extended equipment lifespan: Proper melt stream management minimizes stress on hardware components, contributing to longer equipment life.

- Versatility in material processing: A sophisticated system can handle various resins, including sensitive materials, enabling the ability to adapt to diverse project requirements.

Key Challenges in Achieving Optimal Melt Stream Delivery

So, what's standing in the way of optimal melt stream delivery? Let's take a look at some of the challenges manufacturers and producers face:

Process Variability and Control

Precise control of temperature, pressure, and flow in the melt delivery system is essential for consistent part quality. Manufacturers must synchronize these variables across multiple components, requiring advanced integration and real-time adjustments.

Material Handling and Processing

Achieving optimal melt stream delivery is particularly challenging with heat-sensitive or corrosive materials, as these require careful handling to avoid degradation. Managing fast color changes without sacrificing quality adds another layer of complexity.

Maintaining consistent gate quality over long production runs is crucial for ensuring uniformity and part aesthetics. This demands durable equipment and innovative solutions to maintain uniform flow and minimized wear over time.

Efficiency and Sustainability

Managing energy efficiency throughout the molding process is a key challenge in melt stream delivery. This involves reducing waste and improving overall resource utilization, which directly impacts the melt delivery system's performance. The challenge lies in balancing fast cycle times with part quality and equipment longevity, all of which are influenced by how effectively the melt is delivered to the mold cavity.

System Integration and Optimization

Optimal melt stream delivery depends on the seamless integration of machines, hot runners, and control systems. To achieve this, melt delivery must be optimized across a range of materials and applications, requiring systems that are both versatile and adaptable.

Additionally, the system must be flexible enough to adjust to changing production requirements and market demands, ensuring it can evolve with manufacturing process needs.

Operator Experience

The industry is constantly evolving with many highly experienced machine operators and processing experts retiring. This has created major skill gaps in one of the most critical areas of the injection molding process. Educating and training the next generation is key – and leveraging new technology that is user-friendly, automated, connected and intuitive is the new path to performance and production of quality parts. Products like Husky’s Advantage+EliteTM remote, real-time, predictive monitoring solution are driving industry evolution, and are bridging this knowledge gap by connecting high performance equipment with critical operator feedback.

The Benefits of a Fully Integrated Approach

Husky’s approach involves a unique combination of machine, hot runner, and mold controller, which are designed to work together as an integrated melt delivery system. This holistic approach allows us to optimize performance at every stage, from the initial resin melting to the final mold cavity filling.

Leveraging this approach, system-level enhancements are incorporated to discrete components, enabling challenges to be addressed holistically and resulting in unprecedented levels of control, efficiency, and quality.

A fully integrated approach to melt delivery enables:

- The elimination of variability in the injection molding process

- Higher levels of productivity and operational efficiency

- Reduced waste and lower energy consumption

- Improved part quality, particularly for small, precise parts

- Faster cycle times and reduced time-to-market

- Enhanced flexibility to handle diverse materials and applications

Husky's Integrated Systems: Machine + Hot Runner + Mold Controller

Industry-leading performance doesn't happen by accident – it's the result of intentional design, integrated engineering, and precise execution. This philosophy is at the core of Husky's approach to mastering melt stream delivery, which integrates three key components:

- High-Performance Machines

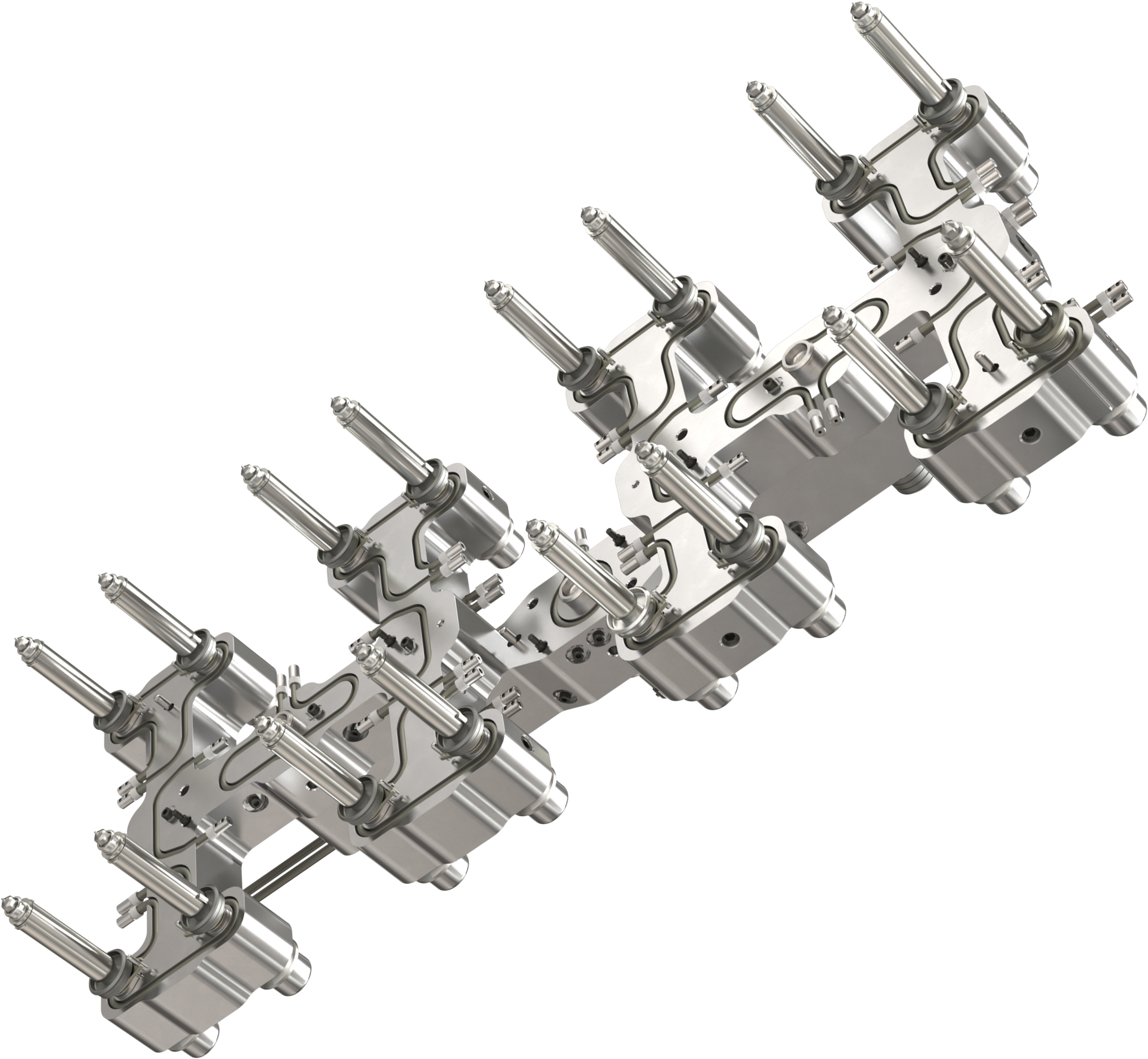

Our machines feature advanced clamp and injection units for precision and speed. A wide screw selection offers different geometries that can be optimized for a diverse range of raw materials and specific molding process conditions, and an intuitive operator interface with intelligent networking ensures ease of use. Energy-efficient features include electric mold stroke, servo-pump powerpack, and an adaptive hydraulic system for optimized performance. The complete system integration between the machine, hot runner, and mold controllers makes it possible to leverage the benefits from corresponding technologies towards every element of the melt delivery system. - Innovative Hot Runner Systems

Husky’s Ultra Helix™ valve gate technology ensures precise alignment and long-lasting gate quality, delivering superior part consistency over millions of cycles. UltraSync™ technology, meanwhile, provides synchronized valve stem movement for consistent part filling, even with close nozzle spacing. Dealing with sensitive materials? That's where UltraMelt™ comes into play. UltraMelt™ offers a non-reactive melt path, minimizing the risk of degradation and ensuring excellent part quality across a wide range of applications. - Intelligent Mold Control

The Altanium® mold controller provides accurate and repeatable temperature control through a single operator interface. Our ART 2.0 (Active Reasoning Technology) takes this further, offering faster heat-up times, 30% lower energy usage, and more precise control compared to competitors.

Beyond the Machine: Husky's Comprehensive Approach

With more than 30 years of engineering and application expertise, Husky offers a global service and support network that goes beyond equipment:

- Lifecycle Support: From refurbishment services to prototyping assistance and advanced flow simulation, we support your operation at every stage of production.

- Process Optimization: Our team provides process and tool optimization, leveraging deep understanding of melt behavior and mold design to enhance production efficiency and part quality.

- Material Expertise: We offer resin testing capabilities and guidance on material selection and optimization, ensuring compatibility with our systems and your production goals.

By partnering with Husky, you gain access to cutting-edge technology and a wealth of expertise that can elevate your injection molding operation to new heights of efficiency and quality.

NEXT STEPS

Book a meeting with a Husky expert to learn how our latest technologies can address your packaging molding needs.

Book a Meeting