How to Leverage Bioresins for Successful Injection Molding

Leading, forward-thinking brands across industries are increasingly opting to replace traditional resins in injection molding for bioresins. This allows them to future-proof their production processes and adapt to fast-changing legislation and consumer preferences.

Bioresins; also referred to as bio-plastics, bio-polymers, and bio-materials; are commercially viable materials derived from renewable biological resources, including:

- Corn or maize starch

- Tapioca starch

- Potato starch

- Sugarcane starch

- Wood pulp cellulose

- Starches derived from vegetable oil

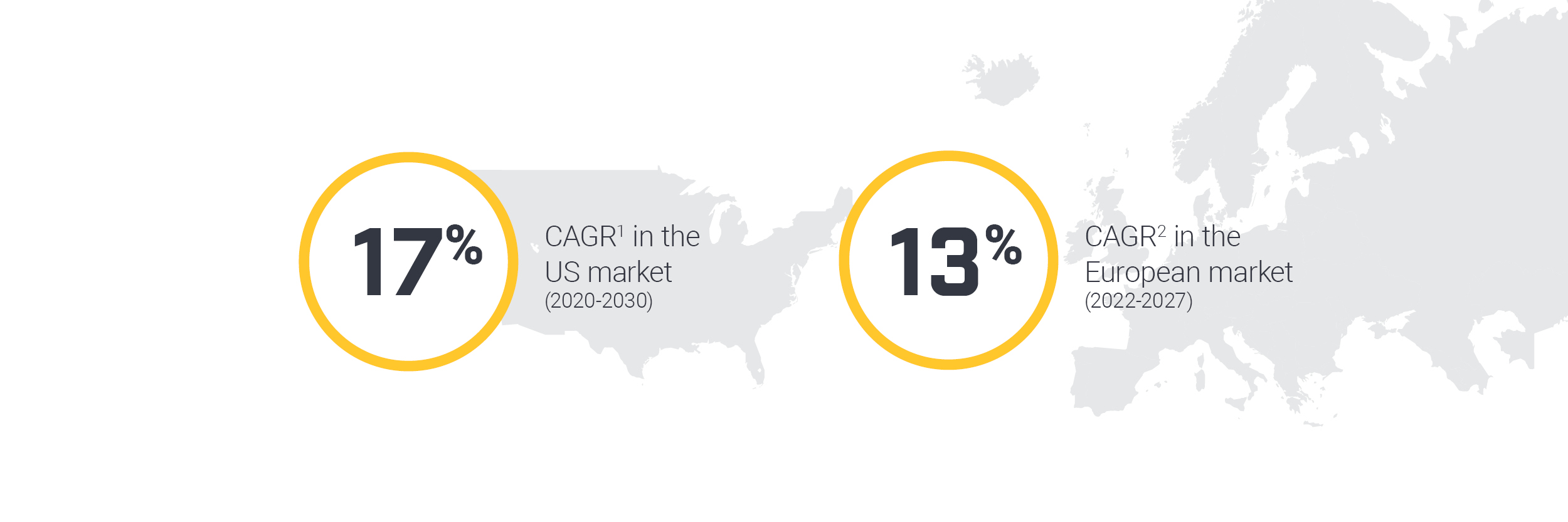

The market for these materials has risen steadily over the last decade and continues to grow at a rapid pace. In the United States, the bioresin market is expanding at a compound annual growth rate (CAGR) of 17% from 2020 to 2030, with projections of a 13% CAGR from 2022 to 2027 in Europe.

Globally, the bioplastics market has an estimated value at over $11.5 billion in 2022, with an expected CAGR of 18.8% until 2030.

This shift represents a significant transformation in the field of injection molding to unlock substantial growth opportunities for brands and producers.

Understanding the Challenges of Bioresins

Bioresins and bio-plastics present unique challenges in the injection molding process. Manufacturers must be aware of them to harness the full potential of these materials.

These challenges include:

Unique Physical Properties: Bioresins often have distinctive physical characteristics, such as high viscosity, susceptibility to leakage, and the need for elevated pressure to fill mold cavities. These properties can make their incorporation into the molding process challenging.

Adapting Manufacturing Processes: Some bioresins are highly temperature-sensitive. This can be problematic for systems not originally designed to handle them.

Transitional Performance and Quality Issues: Bioresins may not initially meet the same quality and performance standards as traditional materials. Molten bioresins tend to be corrosive, potentially compromising processing equipment. These transitional issues may require more frequent equipment maintenance to ensure consistent production and product quality.

Best Practices for Overcoming Bioresin Challenges

A wide range of Husky clients have begun to leverage the benefits of bioresins by following a series of strategic steps to conquer these unique challenges. These include:

Comprehensive Pre-assessment: Before incorporating bioresins into the injection molding process, it’s important to undertake a comprehensive pre-assessment of the material and its suitability for the specific application. This involves examining the compatibility of the part design with the bioresin's rheology, evaluating the necessity for resin testing, setting maximum pressure guidelines, and more.

Manifold Design Optimization: The manifold design must be optimized for bioresins, including ensuring geometrically balanced channels, optimizing channel sizes for low pressures, reduced shear rates, and more.

Optimize Hot Runner Systems: Hot runner systems need to be equipped with a range of features to ensure peak performance to process bioresins. This includes corrosion-resistant components, weepage mitigation elements, plunger valve gates, individual tip control, improved heat distribution to control overshoot, and more.

Consistent Preparation: Maintaining consistent bioresin preparation is essential. Start by ensuring thorough drying before use, with a recommended moisture content of less than 250 ppm to prevent hydrolysis and viscosity degradation. Bioresin should be supplied in foil-lined containers, dried to less than 400 ppm, and should not be exposed to atmospheric conditions after drying.

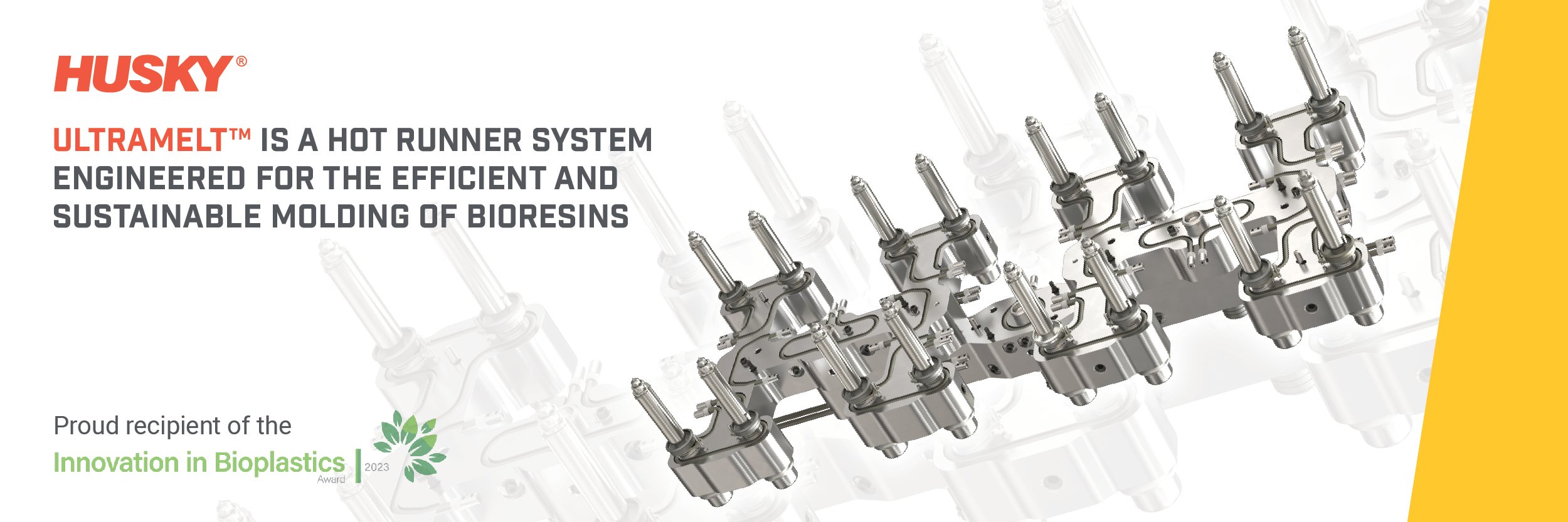

Husky’s UltraMelt™ Hot Runner System for Bioresin Melt Delivery

Husky offers complete system solutions ideal for the successful adoption of bioresin into your injection molding operation. Our UltraMelt™ technology is a premium melt-delivery approach for applications requiring excellent process and thermal control with minimal effect on the resin chemistry.

Husky’s UltraMelt™ hot runner technology

Developed over six years and utilizing over fifty different test manifolds, UltraMelt™ was designed to help users produce small parts with materials more sensitive to temperature and chemical reaction.

UltraMelt™ features 100% non-reactive surfaces and stainless steel components to preserve the sensitive chemistry of bioresin materials to minimize corrosion and other challenges. Configurations are available with a variety of gate methods, nozzle sizes, and actuation styles for both low and high mold cavitations.

Because of these features, UltraMelt™ has become increasingly popular for handling bioresins such as polyhydroxyalkanoates (PHA) and polylactic acid (PLA) when molding small technical or medical parts.

Reach out to a Husky expert to learn even more about UltraMelt and how it can be configured for your specific injection molding applications and conversion projects.

You can also download our recent guide, “How to succeed with bioresin for injection-molded applications” to learn more about the potential of bioresins for successful injection molding.

Learn More